Home > Company News > How to improve the efficiency of sea sand washing equipment?

-

LIMING

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

LIMING

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

Company News

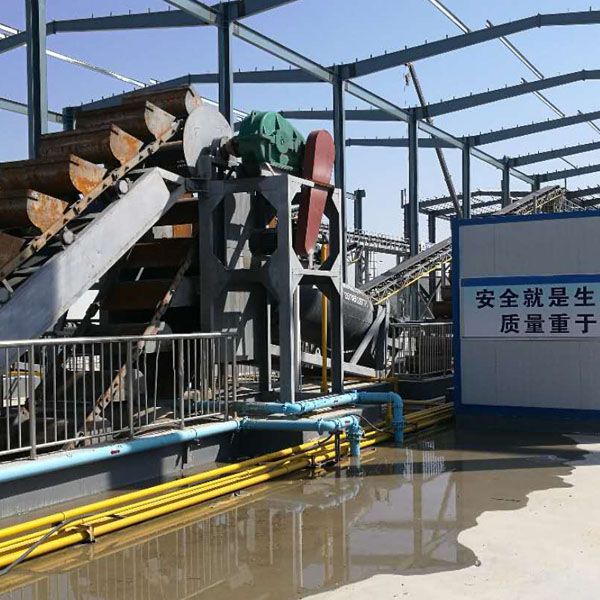

Precautions for use of sea sand desalination equipment:

1. Only after the sand washing equipment operates normally under no load can it enter the sand washing production.

2: evenly add the materials to the sand washing machine to prevent excessive materials and poor sand washing effect.

3: before the stop, should stop feeding, sand washing machine continue to work 5-10 minutes, until the cavity is discharged before stopping, so as to avoid the next time when the boot is dead.

4: in time to remove the waste water and dust precipitation in the sand washing machine, or it will reduce the sand washing effect and increase the load of the equipment.

5: sand washing machine screen wear should be replaced in time.

6: often check the oil level in the sand washing machine, triangle belt into the degree of transmission, gear meshing, and lubrication, connection fastener is loose, to ensure that the machine is in a normal and stable working state, at the same time to the friction parts of full lubrication, regularly add lubricating oil.

7. After adding lubricating oil to the reducer of the haisha desalination equipment for the first time for one month, the lubricating oil should be replaced in time. Filtration should be carried out when filling.

8: equipped with sand washing machine necessary maintenance tools, as well as lubricating oil and corresponding accessories.

-

Tertiary Reversible Impact Hammer Crusher with High Chrome Blow Bar

-

China Wheat and Grain Transport Vibrating Feeder Price in Shanghai

-

Good Quality Heavy Hammer Crusher for Crushing All Kinds of Ores

-

Sand Ore and Coal Vibrating Feeder Machinery Used in Mining Industry

-

High Efficiency Stone Crushing Plant Impact Stone Crusher

-

Sound Equipment Impact Crusher Machine for Stone Crushing Line

-

Mobile Jaw Breaker

-

Energy-Saving Jaw Breaker

-

Low Noise Jaw Breaker

-

High-Efficiency Jaw Breaker

-

Recycling Jaw Breaker

-

Aggregate Jaw Breaker